after receiving the measurement instruction, scan the barcode to confirm the measurement type, scan the QR code to confirm the indicated amount and measurement information, and then perform the operation. After the label is attached, the amount of raw material will be automatically put into the warehouse for management.

after scanning the PC barcode and logging in, reconfirm the QR code of the input raw materials and start production.Put in three-stage roller DISPER MIXER, Nano Disperser equipment to develop high-quality manufacturing process.

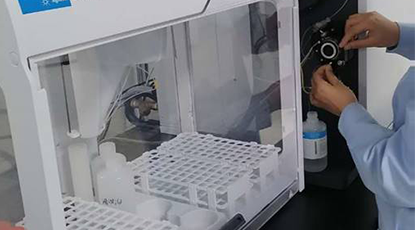

According to the type of container, after using water washing bottle and air washing, automatic/semi-automatic equipment is used for filling.

Using weight screening machines,and other inspection equipment to ensure product quality.

Microbial testing is the basic content of product quality management,which tests the air microorganisms and human flow microorganisms in the raw material room and packaging room to ensure product quality.Microbial testing is carried out by sampling and testing(raw materials/contents/products)before being released from the warehouse.

It is a test from the perspective of consumers,inspecting semifinished products in terms of color,odor and user experience.